2025 ISTA TransPack Hiser

Advancing Global Transport Packaging Standards: ISTA's Collaborative Efforts

Eric Hiser, ISTA VP of Standards & Certification

Presented at the ISTA Forum held on March 24, 2025 in Orlando, Florida

ISTA remains steadfast in its commitment to being the leading resource for improving our world through transport packaging globally. A cornerstone of this mission lies in fostering collaboration among members and gathering insights from industry stakeholders.

This update offers an overview of the diverse feedback mechanisms ISTA leverages to engage with the industry and instigate meaningful change. Additionally, it showcases how the ISTA Standards Council as well as the Certification Council are acting on that feedback to implement changes to existing ISTA tests and enhance existing processes such as lab certification.

Stay informed about ISTA resources and discover how you and your company can contribute to designing effective packaging that minimizes product damage and optimizes resource usage.

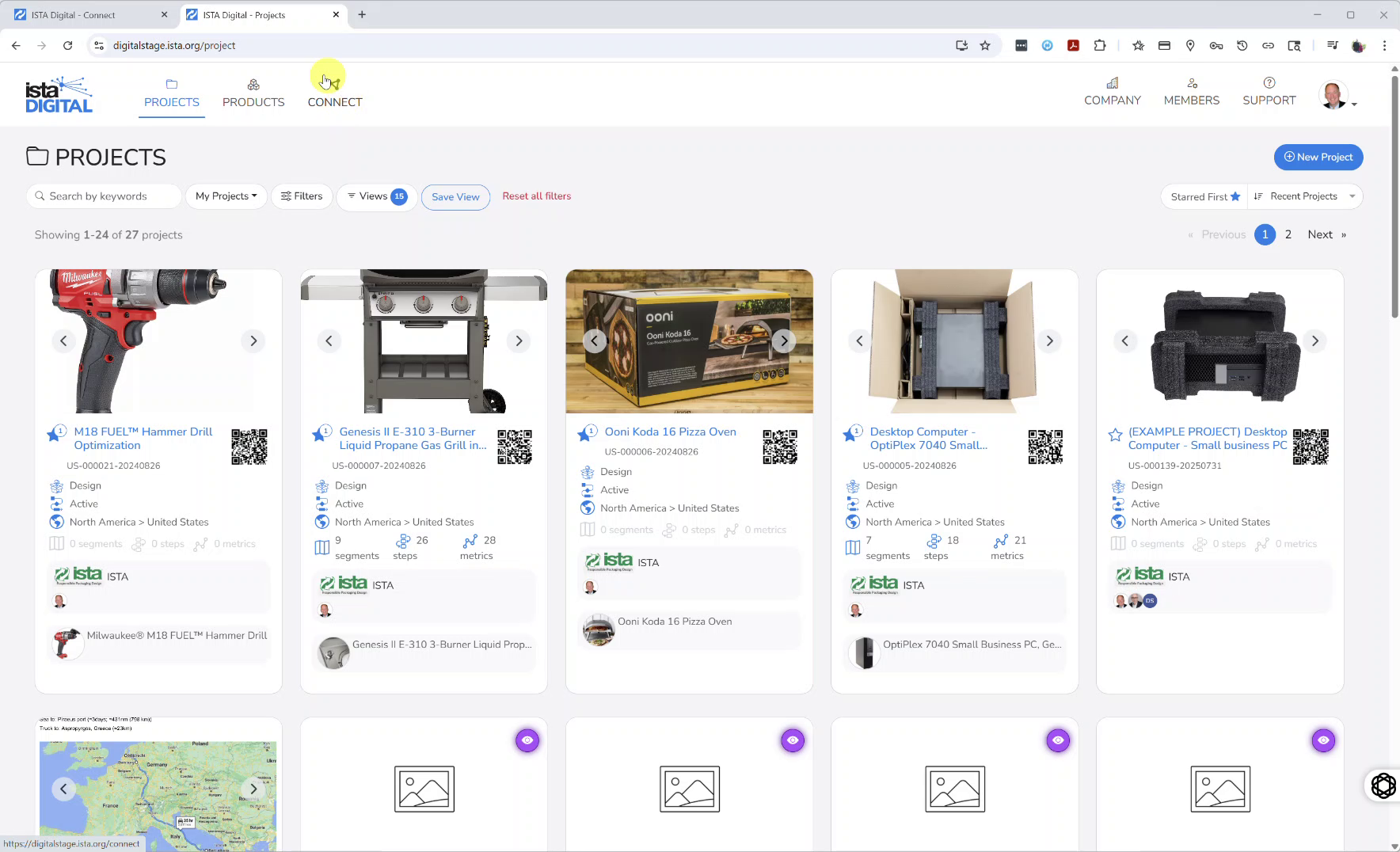

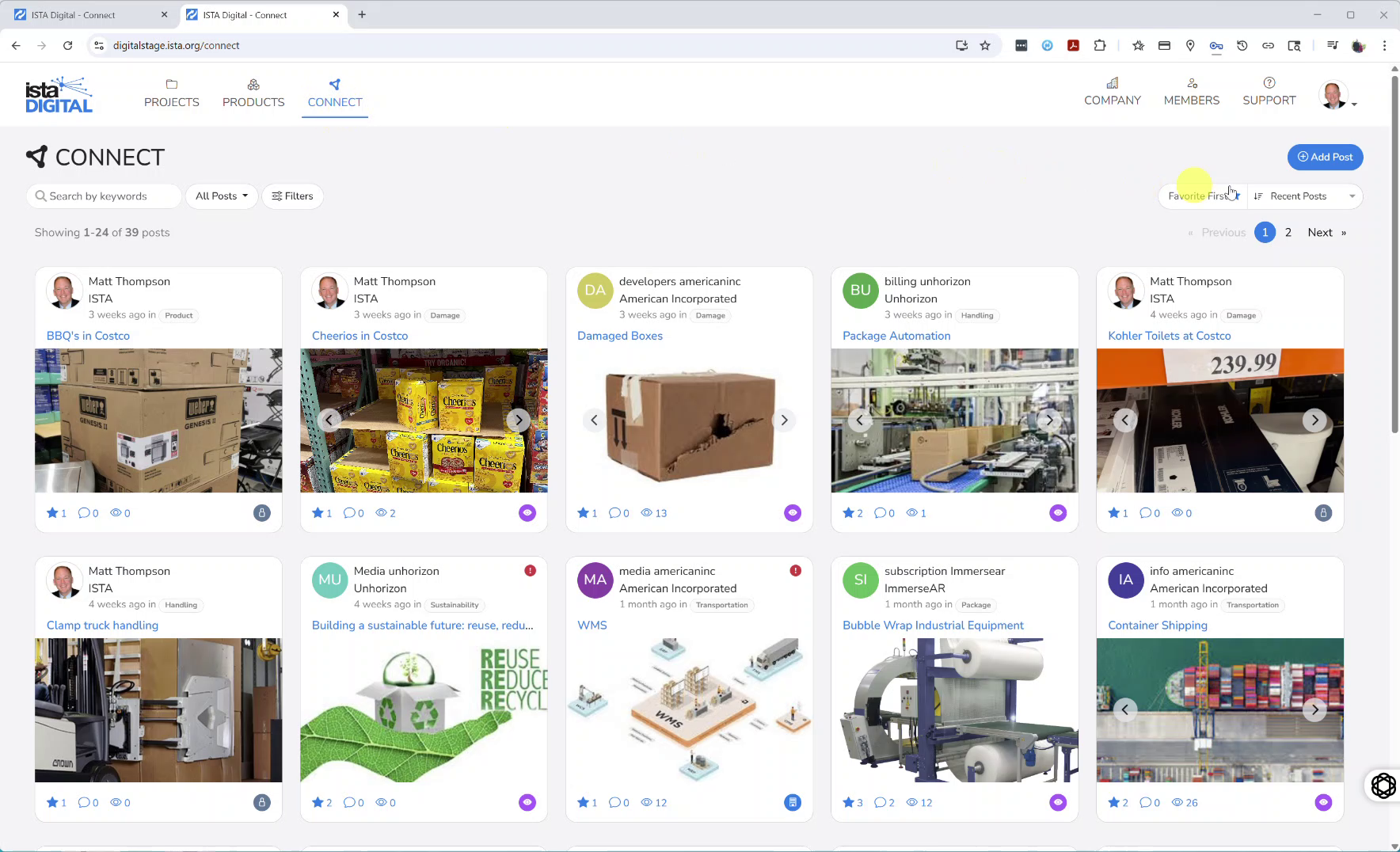

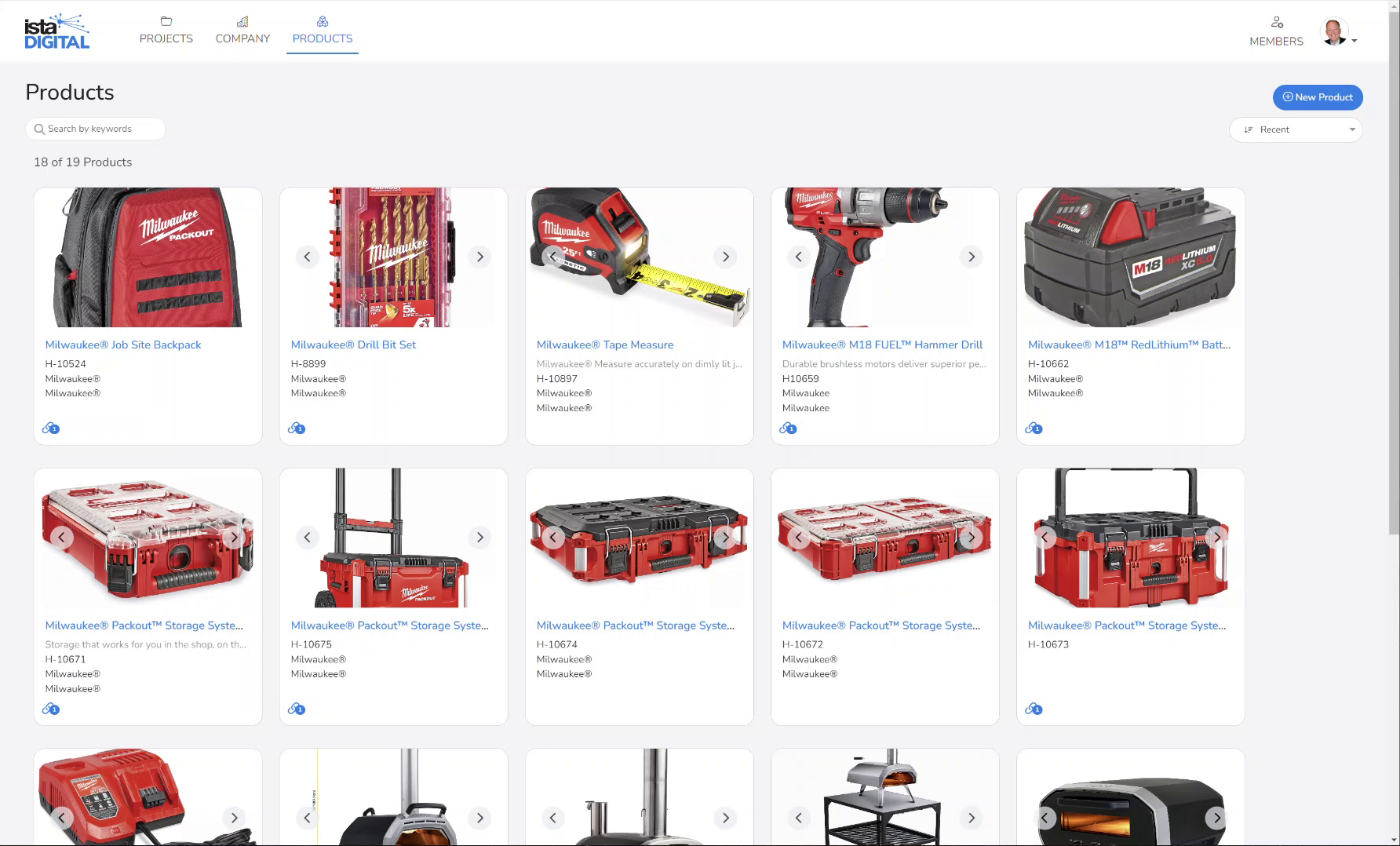

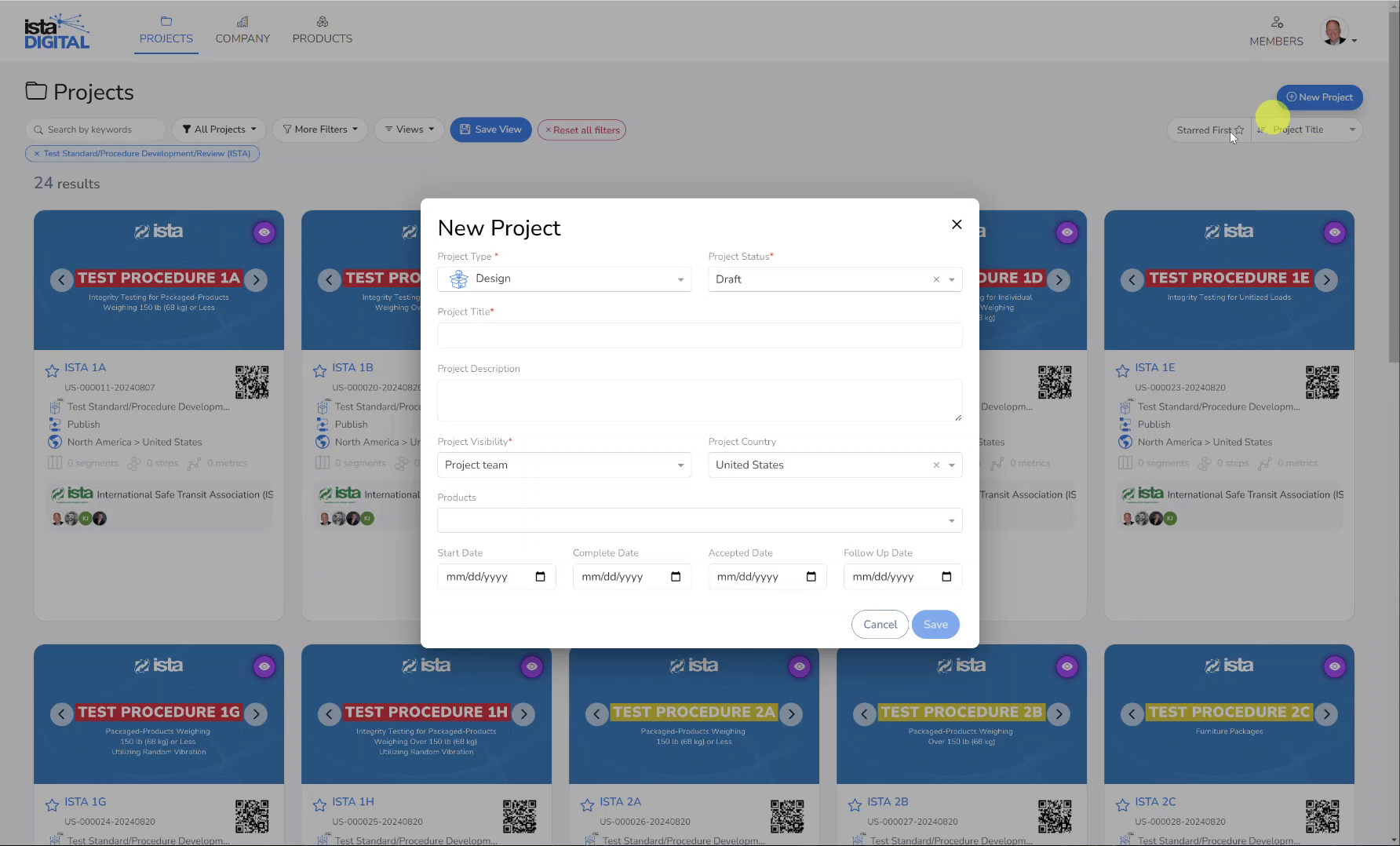

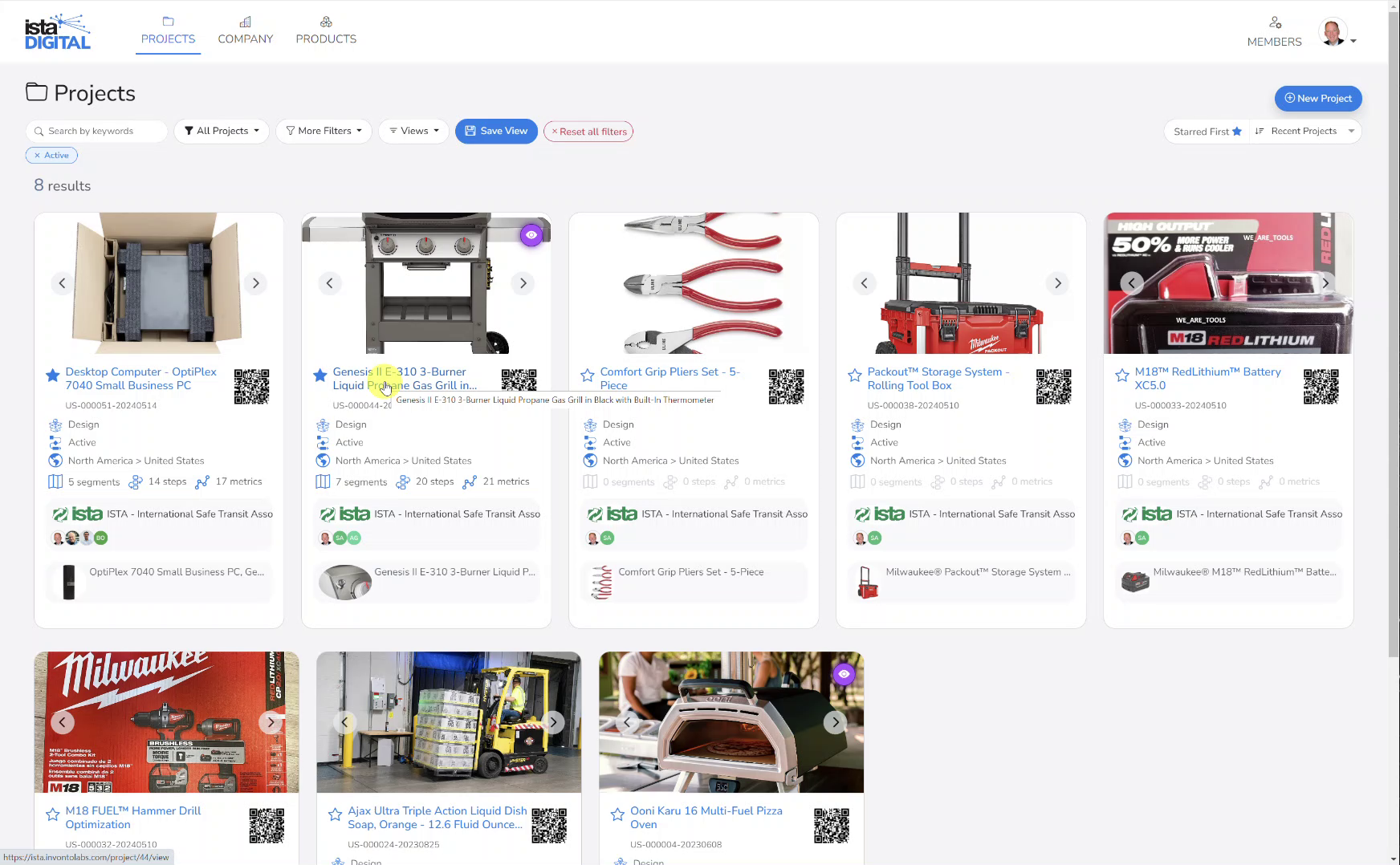

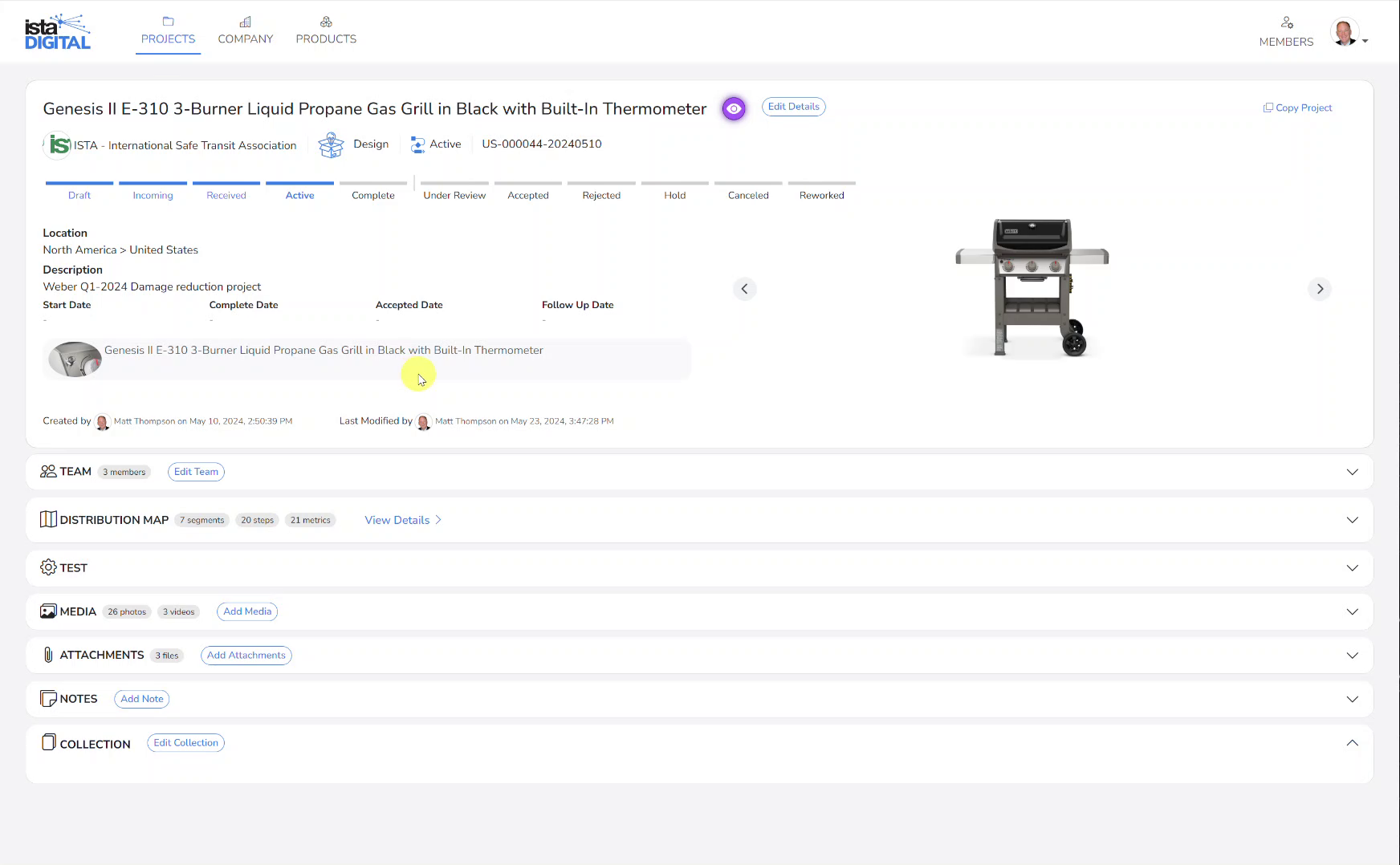

2025 ISTA TransPack Thompson

Latest Updates on ISTA Digital and Education

Matt Thompson, ISTA VP of Program & Market Development

Presented at the ISTA Forum held on March 24, 2025 in Orlando, Florida

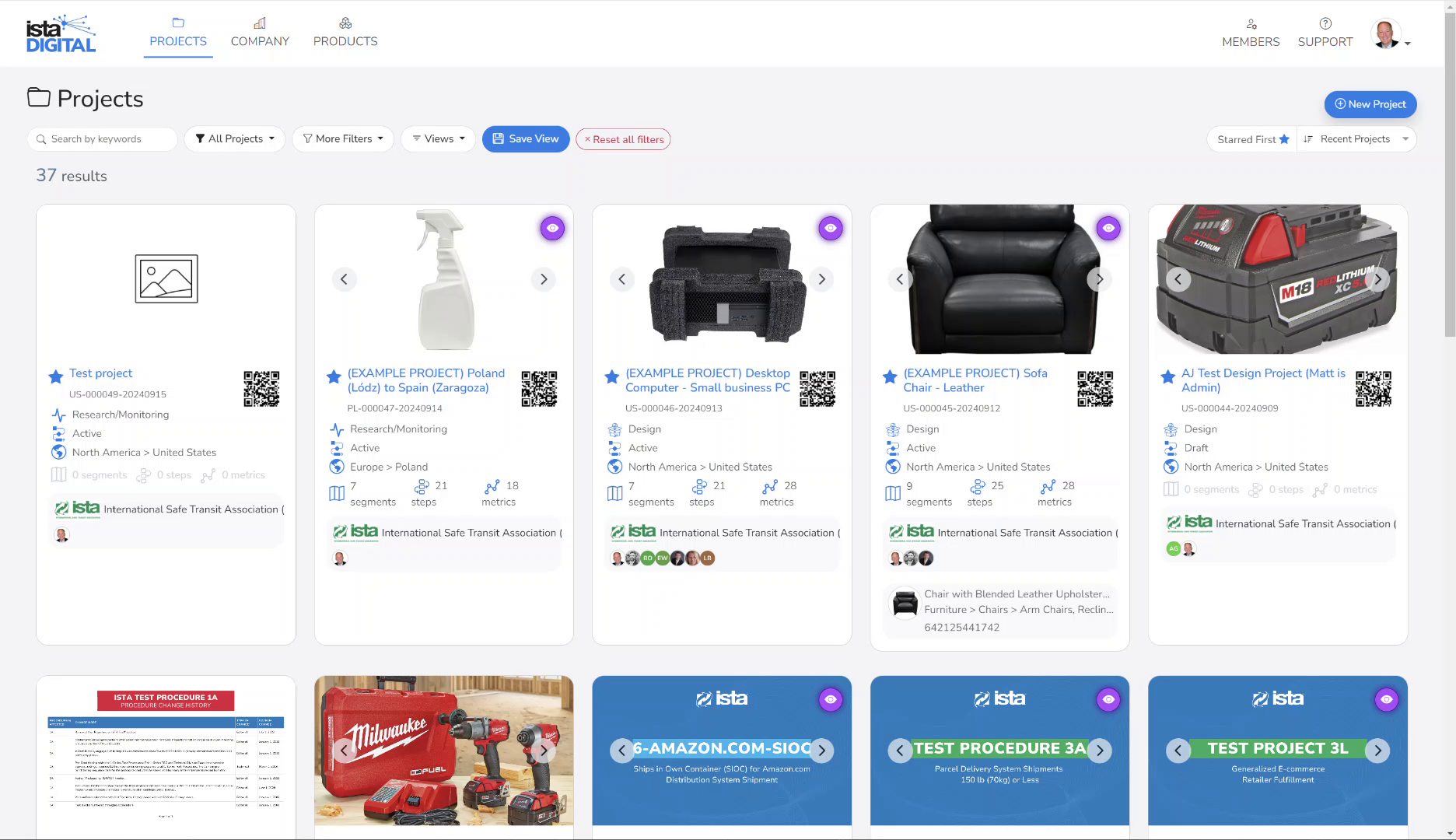

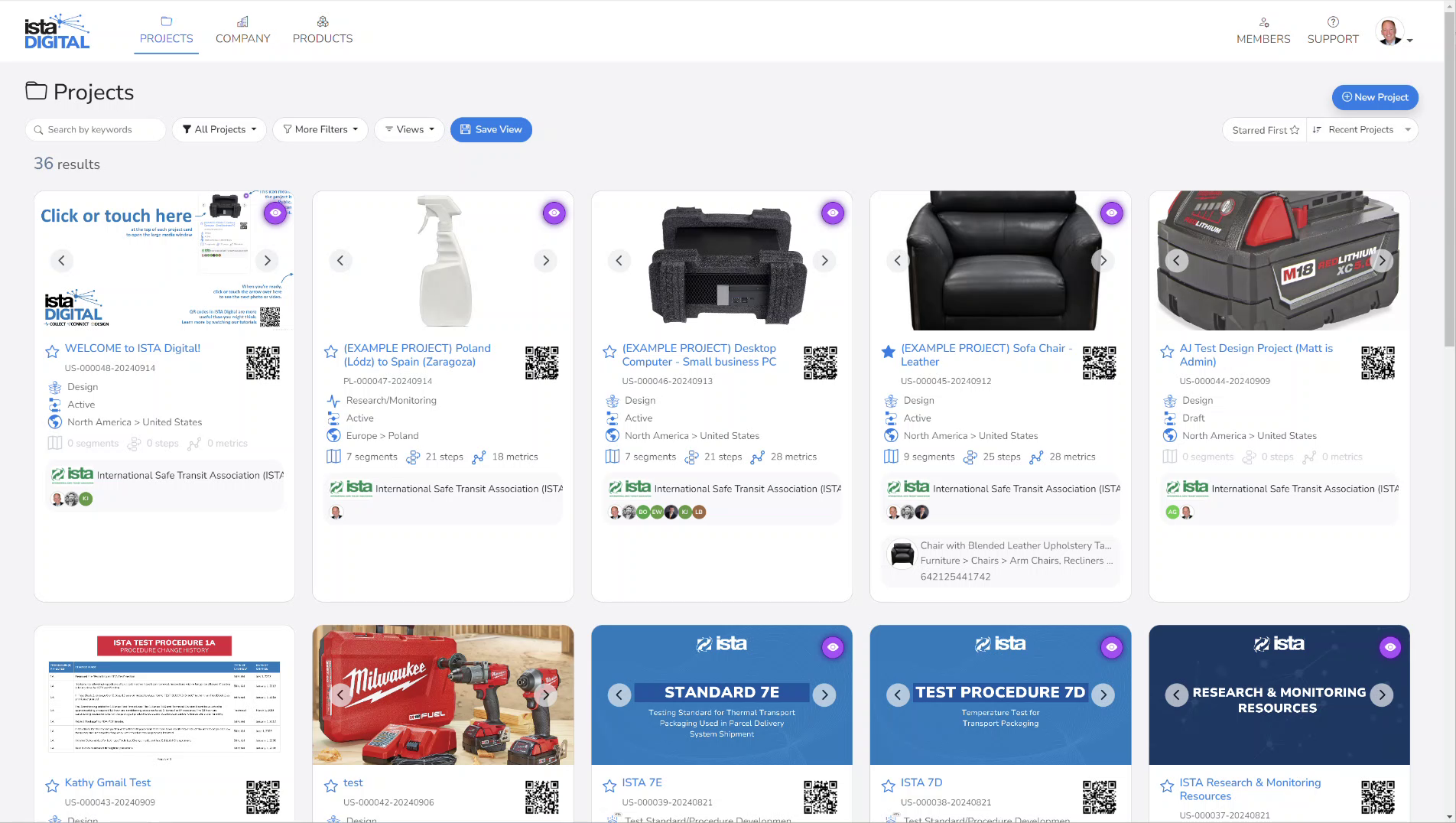

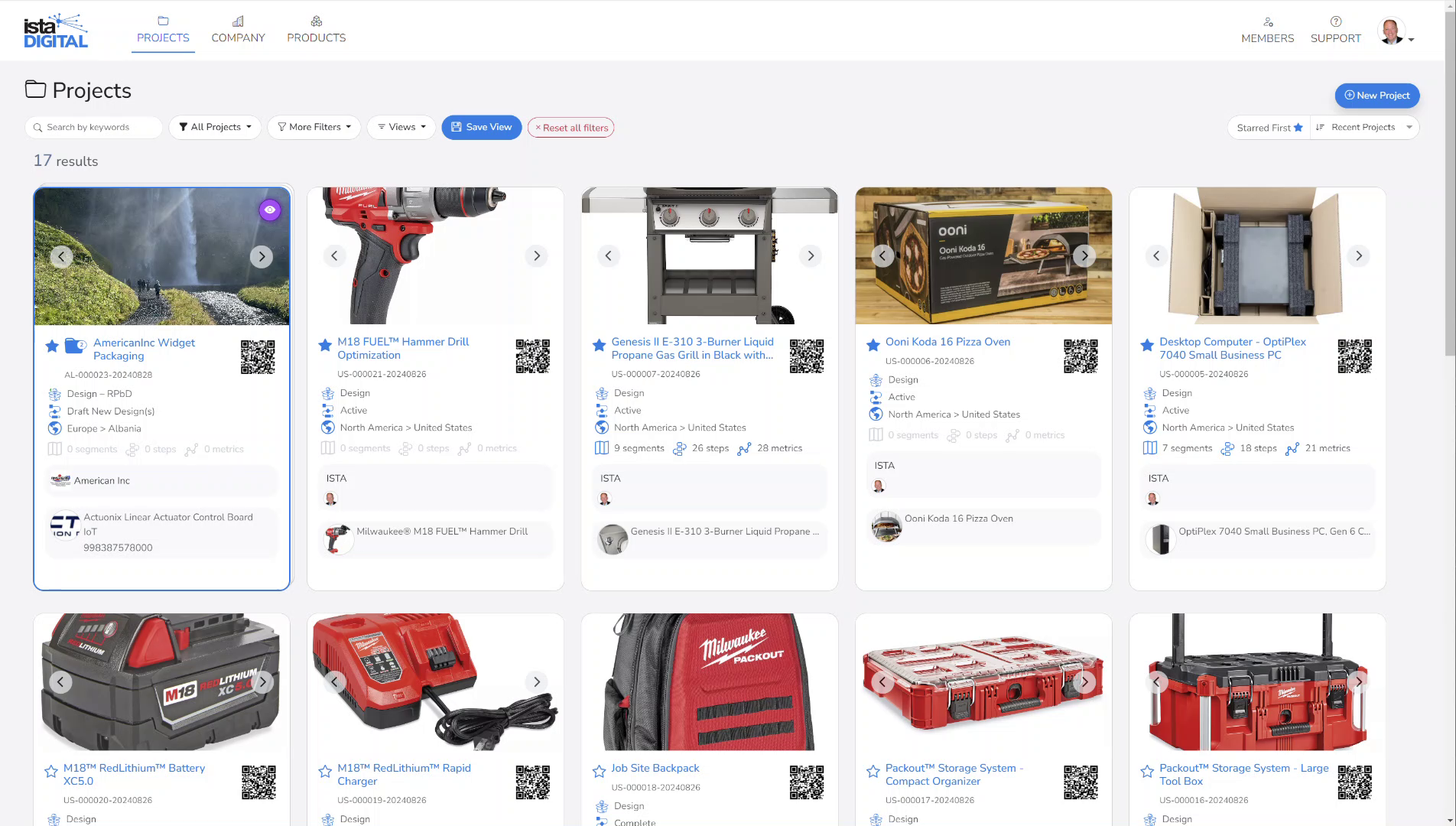

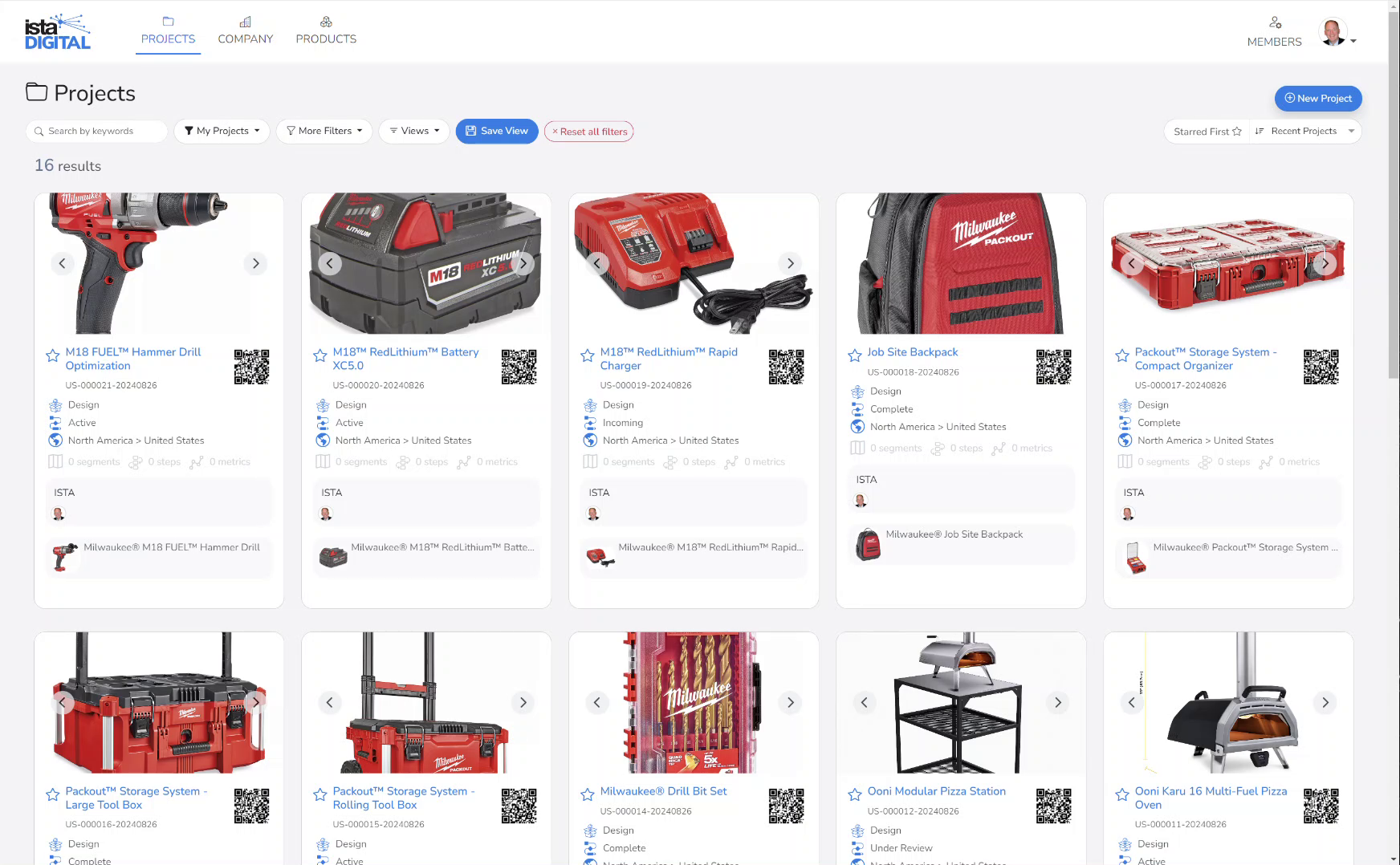

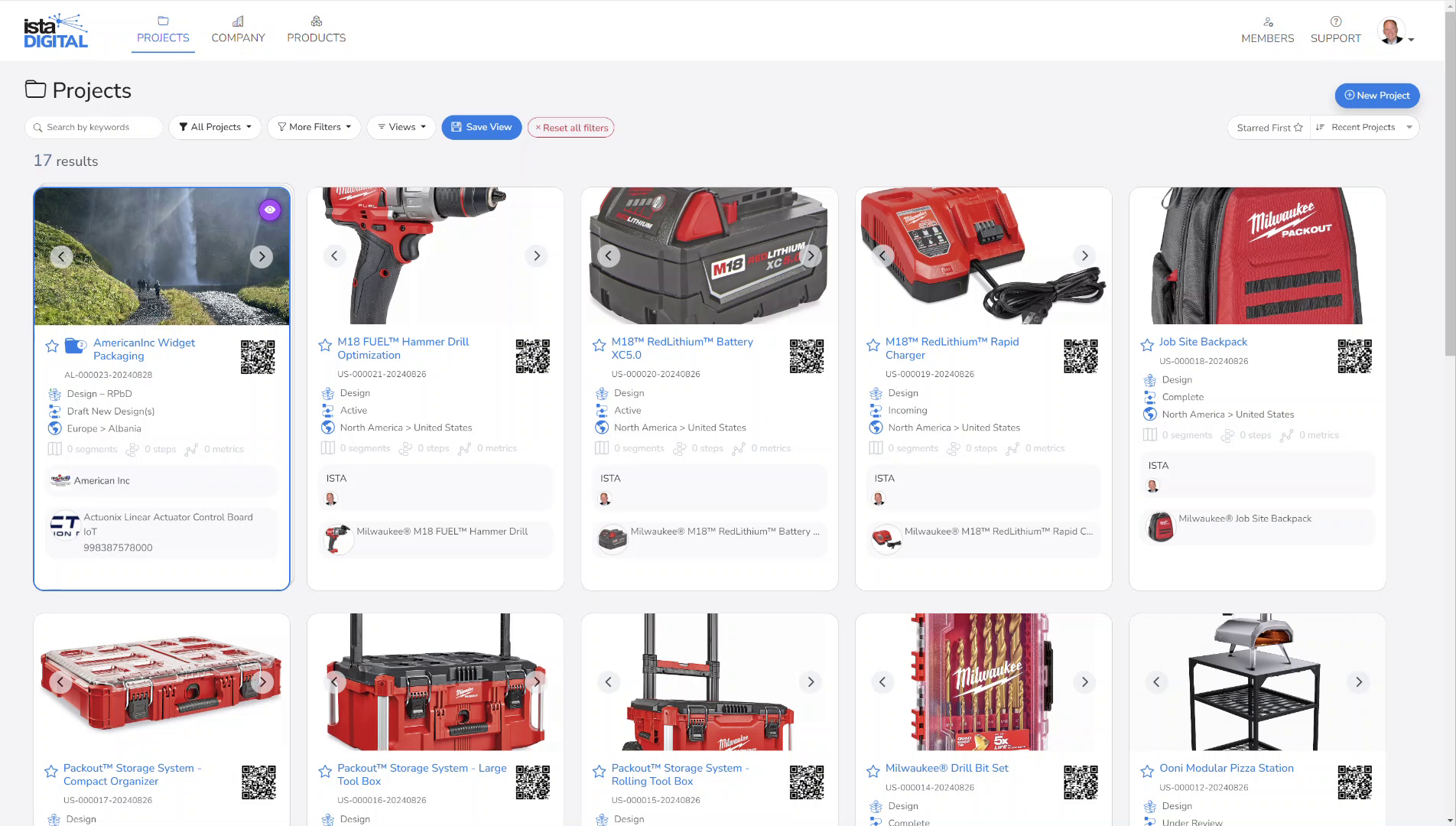

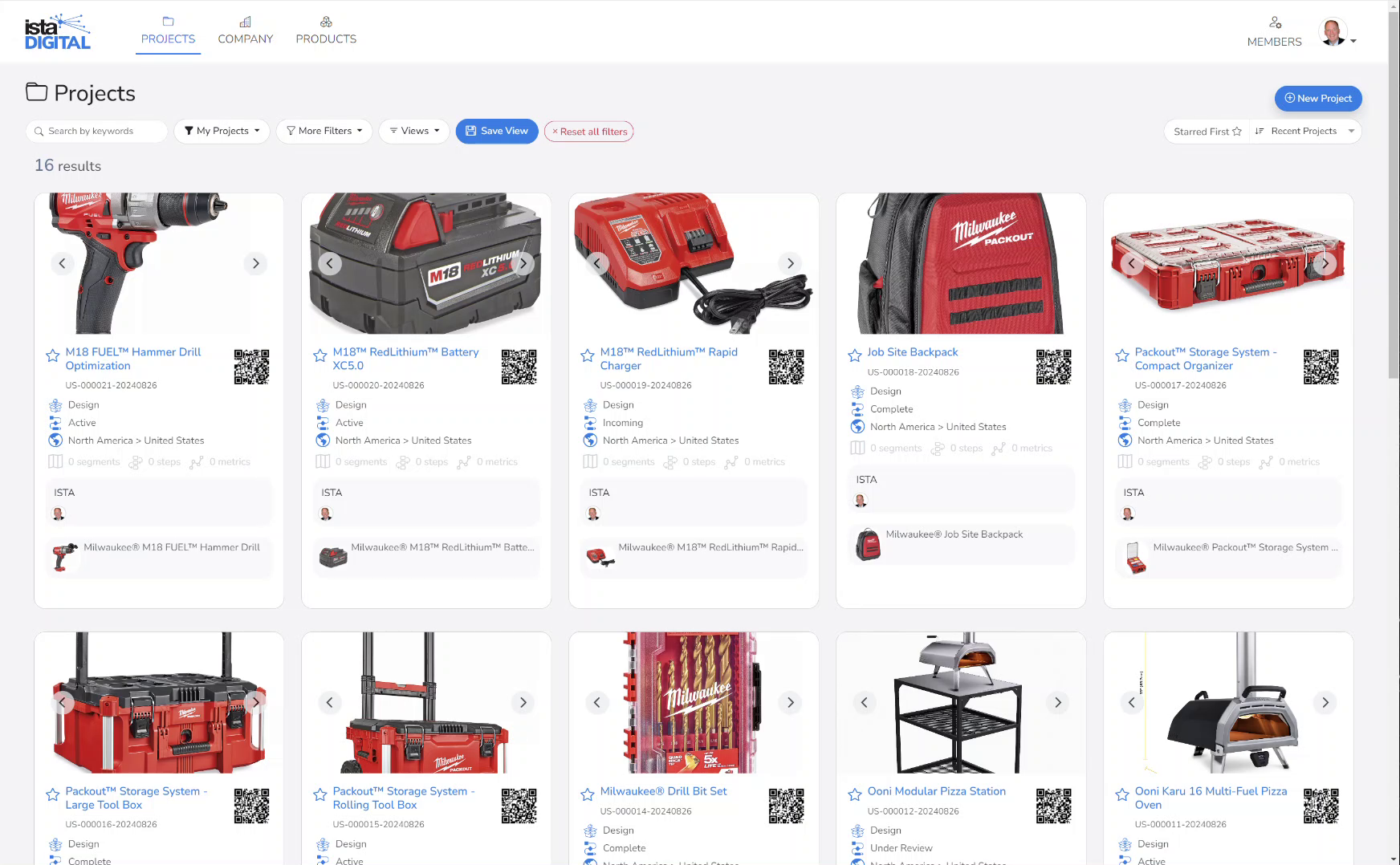

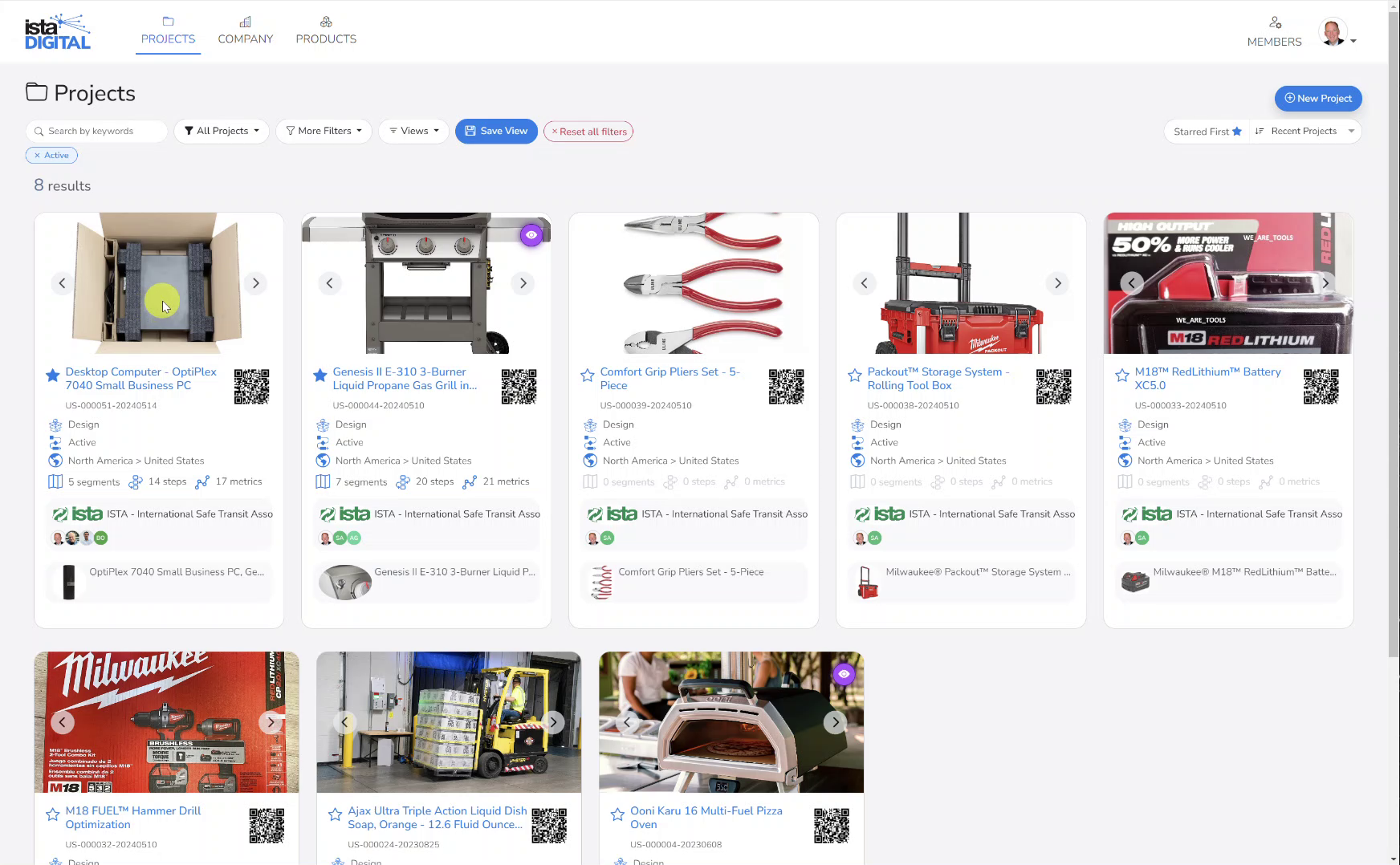

Matt will provide an overview of expert tools available in ISTA's digital cloud platform focused on helping members minimize damage and meet goals for sustainability. Matt will highlight recent updates and share news regarding upcoming improvements to ISTA Digital distribution mapping and our brand-new premium collaboration tool, ISTA Connect.

ISTA continues to invest in education, certification & sharing of event presentations for its members. Matt will provide an overview of ISTA’s educational programs emphasizing what’s new for 2025! Matt will highlight options for ISTA PDP (ISTA Packaging Dynamics Professional) training & certification. He will share the schedule of upcoming Live Virtual Training events. Matt will review new course content including ISTA CC 101 – Principles of Cold Chain Packaging and ISTA’s brand new Test Procedure Training courses!

2025 ISTA TransPack OBanion

Building Transit Hazard Knowledge Through Research

Brian O'Banion, ISTA VP of Research

Presented at the ISTA Forum held on March 24, 2025 in Orlando, Florida

Research remains at the forefront of ISTA's efforts to continue delivering current, and relevant tools the packaging industry can use to design effective packaged-product systems for transit.

Updates will be provided on ISTA’s data collection research project currently underway in China as well as research undertaken by the ISTA Advocate Research & Value Delivery Program and the ISTA Educational Foundation. In addition, future research priorities will be shared.

Gain insights on all the new resources ISTA is developing that will help you and your company design effective packaging that minimizes product damage and optimizes resource usage.

All About ISTA

The International Safe Transit Association (ISTA) is a member-based nonprofit that empowers organizations, and their people, to minimize product damage throughout distribution and optimize resource usage through effective package design. Worldwide, ISTA is the most trusted, knowledgeable and respected authority in predictive package-performance testing and design standards, helping its members develop more effective packaging to withstand the ever-changing risks of the global distribution environment. For more information, visit www.ista.org.

ISTAEF Dave LeButt Award 2024 Sam Sheppard Fidler

The ISTA Educational Foundation (ISTAEF) has honored Sam Sheppard Fidler of Smithers with the 2024 R. David LeButt Award. This prestigious award recognizes packaging professionals for their exceptional contributions to education in transport packaging. Sam shared his acceptance through a video, which was showcased at the 2024 ISTA Forum in San Diego, California.

ISTA Pharma Committee 'Connect': ISTA PCW-01

ISTA Pharma Committee 'Connect' Virtual Meeting

ISTA PCW-01 | Lane Management Whitepaper

February 6th, 2024

Arminda Montero of AbbVie and Karen Greene of Network Partners, the Co-Leads of the ISTA Pharma Committee Lane Management Working Group, shared key aspects of the ISTA PCW-01 | Lane Management Whitepaper.

2023 ISTA Forum | TransPack & TempPack | Houston, Texas

We had a fantastic time hosting the 2023 ISTA Forum, including TransPack & TempPack events on May 1-3 in Houston, Texas! Check out the video and photo gallery to see highlights!

JOIN US IN SAN DIEGO!

Save the date for the 2024 ISTA Forum to be held April 22-24 at the beautiful Marriott Marquis San Diego Marina. We hope you can join us!

Live Demo & Time Saving Features

The ISTA and Specright team held a live demo of PackSight providing an overview of how PackSight can be used to improve accuracy, save time, and promote test team & stakeholder communication for both existing and custom ISTA test procedures. Webinar held March, 2023. Watch now.

ISTA Pharma Committee Technical Exchange Fall 2022

The ISTA Pharma Committee hosted its annual Technical Exchange on September 7th. Discussion topics included an update on the Pharma Committee's progress, a review of the Thermal Shipping System: Performance Qualification (PQ) and Performance Verification (PV) Best Practice Guideline, what's next for the Pharma Committee and a general open discussion.

Click here to access a pdf of the Session.

PackSight Demo & Learn How a Major Brand is Using PackSight

The ISTA and Specright team share a live demo and overview of how PackSight can be used to improve accuracy, save time and promote test team & stakeholder communication for both existing and custom ISTA test procedures. Learn more about PackSight’s Custom Test Builder, brand new global regional vibration profiles and hear some helpful tips and tricks. Plus a top consumer packaged goods company shares how their packaging team is using PackSight in the lab to improve their e-Commerce go-to-market speed and strategies. Webinar held August 10, 2022.

Hear from PackSight User

Watch the video and learn what one of our users has to say about the platform, from how often he uses it, to the time savings he's realized.

2022 ISTA Forum | TransPack & TempPack | San Diego, CA

We had a fantastic time hosting the 2022 ISTA Forum, including TransPack & TempPack events April 11-13 in San Diego, California! Check out the video to learn more.

Join us in Houston, Texas! We are pleased to announce we'll be hosting the 2023 ISTA Forum, May 1-3 at the beautiful Marriott Marquis Houston!

ISTA Pharma Committee Technical Exchange

The ISTA Pharma Committee hosted a special Technical Exchange to continue the industry discussion on how to shape the future of ISTA Standard 20 and 7E as well as review and vote on the next committee activity topics. Meeting was held on February 8th, 2022.

Other links:

PDF of this session presentation: Click here

Session 1 held on October 5th, 2021: Click here

Session 2 held on October 12th, 2021: Click here

Happy Spring Festival by ISTA China Division

The ISTA China Division sincerely wishes everyone a Happy Spring Festival!

Mega Trends and the Impact on Packaging to 2026

Adam Page

Director of Research and Reports

Smithers

A high-level view of the major developments impacting on packaging and an outlook for growth over the next five years based on extensive research across the value chain:

- Headline market overview

- Changing consumer habits and the “new normal”

- Sustainability drivers for packaging

- Impact of supply chain disruptions

- Growth in E-commerce

- Interconnectivity/smart technologies

- Five-year outlook for packaging

Correlation Between Horizontal Acceleration Testing and Tilt Testing for Load Stability

Enrique de la Cruz Navarro

R&D Manager

Safe Load Testing Technologies

Transport simulation is the knowledge area which reproduces the effects of the transport hazards. The accelerations produced during transport affects the transported goods. The onboard acceleration effects could modify the load stability and it could become a risk on the road. Different techniques for transport simulation are used to evaluate the load stability subjected to those forces produced during distribution. Two of these techniques are the horizontal stability test and the tilt test. The horizontal stability test produces an acceleration trapezoidal transient equivalent to the transient recorded on transport vehicles on emergency braking situations, meanwhile the tilt test inclines the test sample using the gravity. The regulations from some countries, like U.S.A, Canada, European Union, New Zealand, Australia, and some others fix the minimum acceleration, in which a load should hold on to road transport for safety reasons. Enrique will share the requirements and boundary limits for a tilt test suitable to evaluate the stability of a unit load subjected to an emergency braking of a vehicle and the considerations that must be considered in the unit load to be analyzed and compare the results with the deformation obtained in a horizontal stability test.

An implementation of Machine Learning for Packaging Evaluation

Euihark Lee

Assistant Professor

Michigan State University School of Packaging

The packaging evaluation is one of the important processes to ensure the functionality of packages. When a new package is produced, the new package goes through the evaluation process to certify the package performance. Many different evaluation methods have been developed over the last few decades, and package evaluation using mechanical tests have been used widely. The goal of mechanical testing is to simulate the environment that the package will face during distribution and consumer usage. However, mechanical testing is a very costly and time-consuming process.

To resolve these issues, we are introducing several packaging evaluation methods using machine learning algorithms. Machine learning is a subset of artificial intelligence (AI) and it can learn and improve performance automatically without being explicitly programmed. In this presentation, two different machine learning applications will be introduced for the packaging evaluation purpose. The first application is estimating box compression strength using a machine learning algorithm, especially an artificial neural network. The next application is evaluating package failure using consumer reviews in the e-commerce platform. The proof of concept through the proposed methods will be discussed with case studies.

Impact of a Non Constant Acceleration Pressure on the Toppling of a Load

Baptiste Boutrige

Researcher

METROPACK

During transport, the acceleration phenomenon is very important, and damages can occur on the carried products because of that. This is a thing we want avoid. It's important to understand how this phenomenon happened to can control and limit these impacts. The purpose of this study is to determine the impact of a non constant acceleration pressure on the toppling of a load and more especially the impact of the acceleration. The study of the pair acceleration-application time of this acceleration will be made because different pair can have the same impact.

Thank You and Happy Holidays!

A 2021 message from A.J. Gruber, ISTA President & CEO.

New ISTA Tests, Research, and Resources

The following webinar was presented as part of the 2021 ISTA Omni-Channel Packaging Strategies Webinar Series.

Eric Hiser

Vice President of Standards and Certification

ISTA

New ISTA Tests, Research, and Resources

ISTA continues to deliver on its vision of being the leading resource for improving our world through transport packaging globally. As part of that vision, ISTA has created a “Distribution Environment Data Collection Program” to improve current testing protocols, add new testing protocols, and create a world-class data repository that can be leveraged by ISTA, and its members, to better model distribution locally, nationally, and internationally.

Updates will be provided on ISTA’s research projects currently underway in the European Union and China as well as high-level results of observational data captured within several e-commerce retailers in North America. Further, summary results from India research will be shared along with other newly developed test methods that address load stability.

Additionally, learn how ISTA, in partnership with Specright, has transformed the way package testing is performed with PackSight a new online test planning and reporting platform. PackSight not only improves efficiencies by automating test calculations, but it also brings visibility to stakeholders across the supply chain by easily sharing unique password protected web-based final test reports. Beyond that, newly released functionality allows you to build a custom test based upon your supply chain or company needs.

Gain insights on all the new resources ISTA is developing that will help you and your company design effective packaging that minimizes product damage and optimizes resource usage.

The Robots Are Coming! Packaging Design for the Post-Pandemic E-com World

The following webinar was presented as part of the 2021 ISTA Omni-Channel Packaging Strategies Webinar Series.

Brent Lindberg

Founder / Head of Curiosity

Fuseneo

Rapid e-commerce growth in combination with labor shortages and sustainability pressure has led to increased automation and demands on packaging. Brent Lindberg will be sharing some useful e-commerce packaging guidelines as well as automation considerations for your next packaging project!

The Evolution of Packaging: Leveraging Testing and Data to Cater to Emerging Markets & Trends

The following webinar was presented as part of the 2021 ISTA Omni-Channel Packaging Strategies Webinar Series.

Jonathan Quinn

Director of Market Development & Sustainability

Pregis LLC

Damon Lucenta

Packaging Manager

Pregis

It’s a whole new world out there. Supply chain and fulfillment are looking vastly different than they did just two years ago. E-commerce, labor shortages, sustainability, and raw materials are reshaping the packaging needs of customers. Join Pregis as they share strategies and tactics to better solve the business challenges of today – and tomorrow.

The Evolution of Omnichannel in Pandemic Society

The following webinar was presented as part of the 2021 ISTA Omni-Channel Packaging Strategies Webinar Series.

Amanda Lai

Food Retail Practice Leader

McMillanDoolittle

Amanda Lai, Food Retail Practice Leader at McMillanDoolittle, presented current research on consumer shopping behaviors during 2021. She also presented case examples of how brands, retailers and service providers have responded with new omni-channel offerings and provided a point of view on outlook for 2022 and beyond.

ISTA Pharma Committee Technical Exchange Session 2

The ISTA Pharma Committee hosted its annual Technical Exchange in October in two virtual meetings. In this second session, the Pharma Committee discussed the latest industry trends along with ISTA Standard 20 and 7E. Meeting was held on October 12, 2021. Link to session 1.

Click here to access a pdf of the Session 2 presentation.

ISTA Pharma Committee Technical Exchange Session 1

The ISTA Pharma Committee hosted its annual Technical Exchange in October in two virtual meetings. In this first session, the Pharma Committee provided an update to the industry on the committee’s latest activities including a glossary of terms and development of guidance documents. Meeting was held on October 5, 2021. Link to session 2.

Click here to access a pdf of the Session 1 presentation.

ISTA Update: September 30, 2021

Learn about what's happening at ISTA! Check out an update on our packaging community from Greg Batt, Chair of ISTA's Global Board of Directors.

Why Transverse Directional Stiffness is the Most Important Stability Factor That's Not Being Tested

Luke Venechuk

Highlight Industries

Director, Packaging Engineering

70% of the world's unitized goods are being stretch wrapped, but as the industry has become more scientific in stretch wrapping there has been one major factor that has not been taken into account because there has never been a test to quantify it: transverse directional stiffness (TDS). This paper will share a new method for testing TDS and demonstrate the critical role it plays in stabilizing unitized goods.

Capturing Meaningful Multi-Axis Vibration and Impact Data

Mike Beckage

Chief Technology Officer

Diversified Technical Systems, Inc.

Accurate real-world acceleration and angular rate data helps us fully understand dynamic motion, and hence perform realistic transportation simulations and impact tests. Sensors and data recorders have varying specifications and functional parameters that must be chosen carefully in order to collect meaningful information. Sensor properties include measurement range, frequency response, AC versus DC response, accuracy, and thermal effects. Data recorders capture time-history information and in order to do so accurately, the relationship between desired bandwidth, filtering, and sampling must be implemented correctly. It's not rocket science, but it's not simple or obvious either. This presentation will cover the fundamental decisions that must be considered when choosing how to collect single or multi-axis vibration measurements or impact data from vehicles, unitized loads, or packages under test. We will also cover basic measurement system architecture and how that relates to these decisions. We will cover pertinent industry standards and recommended practices and provide guidance on how to apply good engineering principles and judgement when designing a measurement system, making set-up decisions, or assessing the quality of collected sensor data. This presentation is essential for anyone who needs to feel confident in the data upon which they make decisions.

Measurement and Analysis of Industrial Forklifts Vibration Levels

Laszlo Horvath Ph.D.

Associate Professor; Director,

Center for Packaging and Unit Load Design

Forklifts are one of the most common material handling equipment used in warehouses and distribution centers. Vibration generated by forklifts may have an effect on the performance of unit loads and product damage rate. Historical research projects focused predominantly on the measurement of vibration for over-the-road transportation. Thus, there is a lack of understanding of the level of vibration caused by forklifts as a function of different factors such as speed, surface quality, forklift type and unit load weight. The goal of this study was to understand how vibration experienced by forklifts is affected by factors such as speed, road conditions, unit load weight, type of forklift, and sensor location. For the study, power spectral density (PSD) was collected using data loggers. Vibration levels were measured for three different industrial forklifts (gas-powered forklift, electric-powered forklift, and reach truck) under two different types of surface (concrete and asphalt). The forklifts were driven at two different speeds (2mph and 3mph) while carrying two different unit load weights (1,500 lbs and 2,500 lbs). For all the conditions, the vibration levels were measured at the forklift carriage and fork tine tips. The results obtained showed that the highest vibrational intensity occurred at 3-4 Hz, while the highest Grms value observed was 0.145 G2/Hz. An increase in the forklift speed caused an increase in vibration intensity. In contrast, an increase in the unit load weight carried by the forklift caused a decrease in vibration intensity. Among the three forklifts studied, the gas-powered forklift had the highest vibration intensity, and forklifts driven on asphalt experienced more vibration. The obtained forklift profile will be used to generate a dynamic test to assess the performance of the pallet on the forklift.

Build Custom Tests with PackSight!

Eric Hiser, Vice President of Standards & Certification, ISTA

Katie Exum, Product Success Manager, Specright

Jill Kurpershoek, Senior Marketing Associate, Specright

The ISTA and Specright team share a live demo of PackSight’s powerful new custom test builder feature that makes it easy for you to customize a test specific to your distribution chain. This webinar also covered new enhancements to the tool’s reporting and delivery capabilities, including adding hi-res photos, videos and online password protected reporting links you can share with your team and customers. Q&A session included. ISTA's PackSight, powered by Specright is an online test planning and reporting platform for ISTA test procedures.

How to Make a Data-Driven Lane Risk Assessment for a COVID-19 Vaccine Delivery

Stefan Braun

SmartCAE

Managing Director

This talk comprises several case studies from Covid-19 vaccine delivery with different labels, 2-8 °C, <-20 °C and < -70 °C with dry ice. This illustrates how the Virtual Cold Chain is used to simulate the risk of temperature excursions on a lane. The versatility and statistical reliability achieved with this strategy go far beyond what can be achieved in traditional purely test-driven approaches. Typical factors that lead to temperature excursions are tolerances in insulation materials and preconditioning processes, ambient temperatures that are different from prequalification test profiles, influence of the sun when the packages are held on the tarmac, temperature differences during conditioning of PCMs, and more. All factors can be included in the Virtual Cold Chain lane risk assessment. A large set of simulation scenarios is set up to analyze the influence of each individual factor on the risk of temperature excursions. Stability data of the transported drug are used to rate the severity of the excursion, and to decide whether it is an uncritical temperature label excess, or a product integrity violation. Using the parameters excursion rate and rate of product loss, which are available from the simulation, the total costs of ownership for different packaging solutions are determined. This systematic approach enables finding the optimal packaging for a specific lane under cost/risk considerations.

Frustration-Free Packaging Programs at Amazon: Status & Update

Sabrina Burkhardt, Customer Packaging Experience (CPEX) Lab Manager, Amazon

This webinar highlights the Frustration-Free Packaging Programs’ impact in delighting customers through reducing product damage rates and packaging waste. Beginning with a recap of the development and importance of the ISTA 6-Amazon.com SIOC test, this presentation will provide an overview of both successes and learnings from our original Non-Sort Incentive program and what’s coming next: The Frustration-Free Packaging Programs Incentive Expansion, announced June 1, 2021 for North America. After a walkthrough of the 2021 incentive program, we will close with several case studies from brand owners that have redesigned their packaging to be easy-to-open, 100% recyclable, and can be shipped without adding protective packaging.

Frustration-Free Packaging Programs at Amazon: Status and Update

Sabrina Burkhardt, Customer Packaging Experience (CPEX) Lab Manager, Amazon

This webinar highlights the Frustration-Free Packaging Programs’ impact in delighting customers through reducing product damage rates and packaging waste. Beginning with a recap of the development and importance of the ISTA 6-Amazon.com SIOC test, this presentation will provide an overview of both successes and learnings from our original Non-Sort Incentive program and what’s coming next: The Frustration-Free Packaging Programs Incentive Expansion, announced June 1, 2021 for North America. After a walkthrough of the 2021 incentive program, we will close with several case studies from brand owners that have redesigned their packaging to be easy-to-open, 100% recyclable, and can be shipped without adding protective packaging.

2021 ISTA Annual Membership Meeting

Learn more about board member updates, a financial and membership review, and some of ISTA’s major focuses in 2021.

ISTA Update: May 27, 2021

Learn about what's happening at ISTA! Check out an update on our packaging community from Greg Batt, Chair of ISTA's Global Board of Directors.

Laboratory Techniques to Simulate Dunnage Used in the LTL Distribution Environment Webinar

Eric Hiser, Vice President of Standards & Certification, ISTA

Kyle Dunno, Assistant Professor, RIT – Packaging Science Program

Jim Bisha, Manager - Packaging Optimization, Chainalytics LLC

Brennan Lytle, Research Associate, Clemson University

Dunnage materials are widely used in the less than truckload (LTL) shipping environment, due to the wide array of freight handled on a daily basis. While the dunnage is designed to restrict the motion of freight, in doing so, it can sometimes damage the freight as a result of certain events (shocks and vibration hazards) occurring during shipment. The premier transport test standard for simulating general LTL transport is ISTA Procedure 3B. This standard exposes packaged products, both individual and unitized, to different transport hazards commonly experienced by this mode of transport. While the test standard challenges the freight to different laboratory simulated hazards, missing from the standard is the interaction between freight and dunnage material. It was this identified gap that led to the formation of a workgroup to investigate the interaction during shock and vibration events. This webinar provides an overview of the workgroups progress towards development of a test method(s) including investigate work conducted at university partners RIT and Clemson.

PackSight Updates & New Custom Test Builder Feature Coming Soon

The ISTA and Specright team recently held a live demo of PackSight at the 2021 Virtual ISTA Forum. The demo included an overview of the new tool and platform updates. March 31, 2021

Major Brand Uses PackSight to Improve their e-Commerce Strategies & Custom Test Builder Feature

The ISTA and Specright team conducted a live demo of PackSight, a new online test planning and reporting platform for ISTA test procedures. Click here to view the webinar Q&As. February 25, 2021

Supplier Uses PackSight in the Lab to Save Time and Ramp Up Testing Volume

Advance Packaging Corporation took us in the lab to share how they've been using PackSight to save time and ramp up testing volume. The ISTA and Specright team provided more helpful tips, platform updates and concluded with a Q&A session. Webinar held November 18, 2020. Click here for the answers to the Q&A portion of the webinar!

Introduction to ISTA

Learn about the International Safe Transit Association (ISTA) and the benefits we offer to packaging, transportation, and supply chain professionals world-wide.

ISTA Update: September 21, 2020

Greg Batt, Chair of ISTA’s Global Board of Directors shares an update about what’s happening with ISTA’s packaging community. Check it out to learn more!

ISTA Update: July 28, 2020

Learn about what's happening at ISTA! Check out an update on our packaging community from Greg Batt, Chair of ISTA's Global Board of Directors.

PackSight Demo of ISTA 6-Amazon SIOC Test and Tips & Tricks

The ISTA and Specright team conducted a live demo of PackSight and the ISTA 6-Amazon SIOC Test. Webinar held July 23, 2020.

Click here for the answers to the Q&A portion of the demo!

2020 ISTA Annual Membership Meeting

Download additional ISTA Update slides: Click here.

PackSight Demo, Benefits and Getting Started

The ISTA and Specright team conducted a live demo of PackSight, a new online test planning and reporting platform for ISTA test procedures. Webinar held May 12, 2020. Click here for the answers to the Q&A portion of the demo.

Creating a Metric for CPG Distribution Unsalables: A Demonstration of Concept Project

Dennis E. Young

Specialist, Michigan State University

School of Packaging

Pallets and Mold Control

Ralph Rupert

Manager - Unit Load Technology

Millwood, Inc.

A Visual Study of Cushion Geometry's Effect on Performance

Bill Green

IBM

Techniques for Reducing the Time of Laboratory Vibration Simulation

Kyle Dunno

Clemson

Benchmarking of Industrial Machine Wrap Stretch Film

Larry Effler

The Dow Chemical Company

How to Design an Efficient Unit Load By Considering the Stiffness of the Pallet

Laszlo Horvath

Virginia Tech

Ergonomics and Manual Material Handling

Susie Elkins

Millwood, Inc.

Laboratory Evaluation of ASTM D4169 (Current and Proposed) and ISTA Vibration Profiles

Michael Morrow

Material and Performance Evaluation of Shipping Containers Utilizing Alternate Materials and Styles

Monica Habash

West Pharmaceutical Services

Systems Based Design of Global Supply Chains

Marshall White

Professor Emeritus

White and Company LLC

Dissecting Containment Force, Load Compression, Film Stiffness, and their Roles Stabilizing

Luke Venechuk

Highlight Industries, Inc.

Being a Packaging Engineer at a Food Manufacturer in this Omni-Channel World

Greg Roskos

The J.M. Smucker Company

Adapting to the Re-configuration of the Retail Supply Chain

Greg Fornaseiro

Home Depot

Application of a Triboelectric Energy Harvester in Transport Packaging

Greg Batt

Assistant Professor

Clemson University

Comparative Measurement and Observation from Intermodal Transportation

Eric Joneson

Vice President of Technology

Lansmont

A New Look at Simulation Testing to Replicate Packaging and Product Damage in the Field

Alex Hagedorn

GE - Appliances & Lighting

Innovating Your Innovations

Robby Martin

Engineer Specialist

Bush Brothers & Co.

Over-the-Road Load Shift Investigative Case Study

Eric Joneson

Vice President of Technology

Lansmont

The Effect on Non-Chemical Phytosanitary Treatment on Packaging Integrity of Unitized Products to Prevent the International Spread of Invasive Plant and Animal Species

Marshall White

Professor Emeritus

Virginia Tech

Stability Palletised Corrugated Packaging in Modern Supply Chains

Gerard van den Boogaard

Expertise Manager Supply Chain

Smurfit Kappa Development Centre

Effects of Social Media and Packaging on e-Commerce Shippers

Jack Mahoney

Brand Manager

Pregis

Developing Thermal Data Analysis Standards: Algorithms for Developing Temperature Test Profiles from Ambient Lane Data

Bernard McGarvey

Retired

Paul Harber

Founder

Parental Supply Chain

Developing Climatic OQ Thermal Challenge Profiles

Bryan Cardis

Consultant Cold Chain and Packaging Engineer

Eli Lilly and Company

Jeffrey Chida

Consultant Engineer

Eli Lilly and Company

Retail Supply Channels for CPGs In India: An Evaluation of Handling, Storage & Transportation in the Distribution Environment

Jay Singh

Professor & Packaging Program Director

Cal Poly State University, San Luis Obispo

Dynamic Highlights of Comprehensive Intermodal Distribution Measurement Study

Eric Joneson

Vice President of Technology

Lansmont

ISTA Testing Laboratory Certification Portal

ISTA Lab Certification Portal

Amazon Update on Testing and Certification

Brent Nelson, Amazon Principal Product Manager, Packaging, Customer Packaging Experience

This webinar was held August 15, 2019 for ISTA Certified Laboratories.