ISTA Packaging Dynamics Professional Certification (Additional Fee)

Room: Cloud 1Get ISTA Packaging Dynamics Professional (ISTA PDP) Certified with this comprehensive in-person training. To receive ISTA’s Packaging Dynamics Professional (ISTA PDP) Certification, you must complete all six PDP courses and pass the corresponding exams. Take the ISTA PDP Certification exams conveniently online through ISTA’s learning platform—complete with full video presentations and course content to help you prepare and succeed. PDP courses included:

- PDP 101: Principles of Distribution Packaging

- PDP 201: Atmospheric & Compression Hazards in Transit

- PDP 202: Shock & Drop Hazards in Transit

- PDP 203: Vibration Hazards in Transit

- PDP 204: Test Laboratory Operations & Instrumentation

- PDP 205: Test Procedures & Enhanced Simulation Testing

Click here to view the full schedule and rates with and without Forum registration.

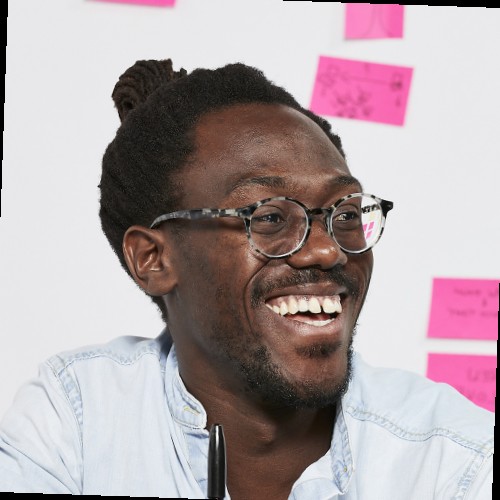

Led by expert ISTA Instructor Giovani Rissi, this in-person training is a convenient option to becoming a certified ISTA Packaging Dynamics Professional.

.jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpeg)

.png)

.png)